A Lithium Cell-Making Machine is a specialized piece of equipment designed for the automated and precise manufacturing of lithium cells, which are the building blocks of lithium-ion batteries. These machines play a crucial role in the mass production of batteries for various applications, including electric vehicles, consumer electronics, and renewable energy storage. Here are key components and functions associated with Lithium Cell-Making Machines:

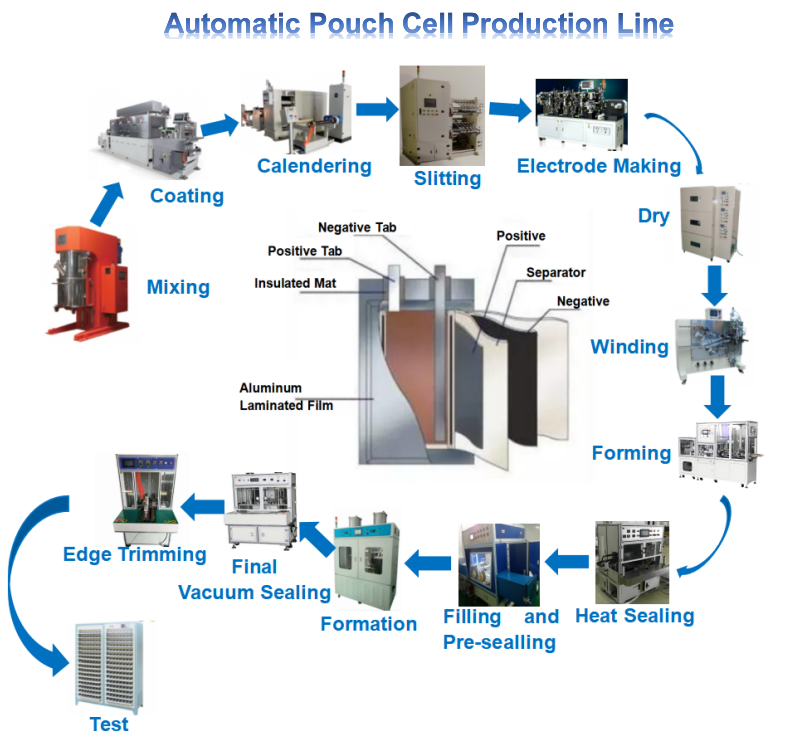

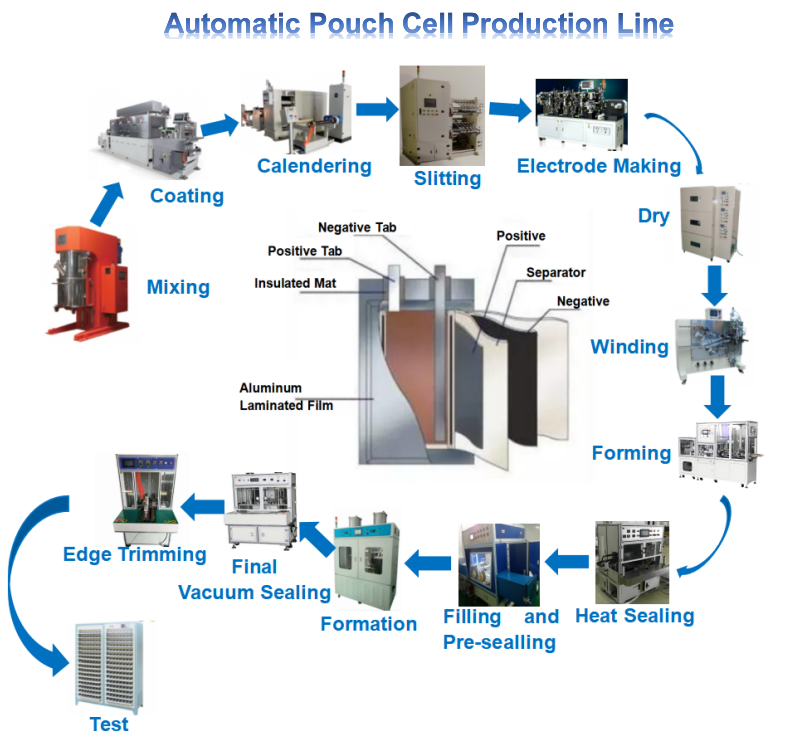

1. Electrode Coating System:

Battery Production Machine typically include an electrode coating system. This system applies a thin and uniform layer of electrode materials (cathode and anode) onto current collectors. The coating thickness is a critical factor influencing the performance of the lithium cell.

2. Calendering Equipment:

Calendering is a process that involves pressing the coated electrode materials to achieve a specific thickness and density. Lithium Cell-Making Machines often incorporate calendering equipment to ensure the electrodes meet precise specifications.

3. Electrolyte Filling System:

After the electrodes are coated and assembled, the lithium cell needs to be filled with electrolyte. Lithium Cell-Making Machines include systems for accurately injecting the electrolyte into the cell, ensuring the right amount and composition.

4. Cell Assembly and Encapsulation:

These machines handle the assembly of different components, including separators and current collectors, to form a complete lithium cell. The assembled cell is then encapsulated in a protective casing, often made of materials like aluminum or steel.

5. Sealing and Welding Systems:

To ensure the integrity of the lithium cell, Lithium Cell-Making Machines incorporate sealing and welding systems. These systems securely seal the cell to prevent leakage and maintain a controlled environment within the cell.

6. Formation and Testing Stations:

Lithium cells undergo a formation process, which involves initial charge and discharge cycles to stabilize their electrochemical properties. Testing stations within the machine monitor voltage, capacity, and other parameters to ensure the quality and reliability of each cell.

7. Quality Control Measures:

Advanced Lithium Cell-Making Machines integrate quality control measures throughout the manufacturing process. This includes automated inspections, optical checks, and data monitoring to identify and reject cells that do not meet specified standards.

8. Automation and Robotics:

These machines often incorporate automation and robotics for handling and transporting components, reducing manual intervention, improving efficiency, and ensuring precision in the manufacturing process.

9. Scalability:

Lithium Cell-Making Machines are designed to be scalable, accommodating different production volumes. This scalability is crucial for meeting varying market demands and adjusting production levels based on specific requirements.

10. Integration with Industry 4.0 Technologies:

- Many modern Lithium Cell-Making Machines integrate with Industry 4.0 technologies, allowing for real-time data collection, connectivity, and smart monitoring. This enhances overall efficiency, predictive maintenance, and quality control.

In summary, Lithium Cell-Making Machines are sophisticated pieces of equipment that automate and streamline the production of lithium cells. Their integration of various processes ensures the consistent and high-quality manufacturing of lithium-ion batteries, contributing to the advancement of energy storage technology.

fr

fr en

en de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

réseau ipv6 pris en charge

réseau ipv6 pris en charge