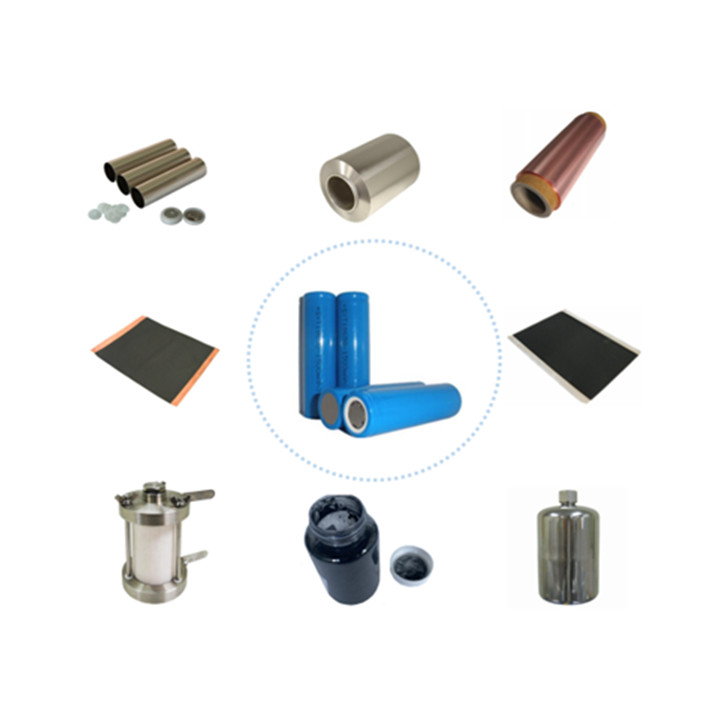

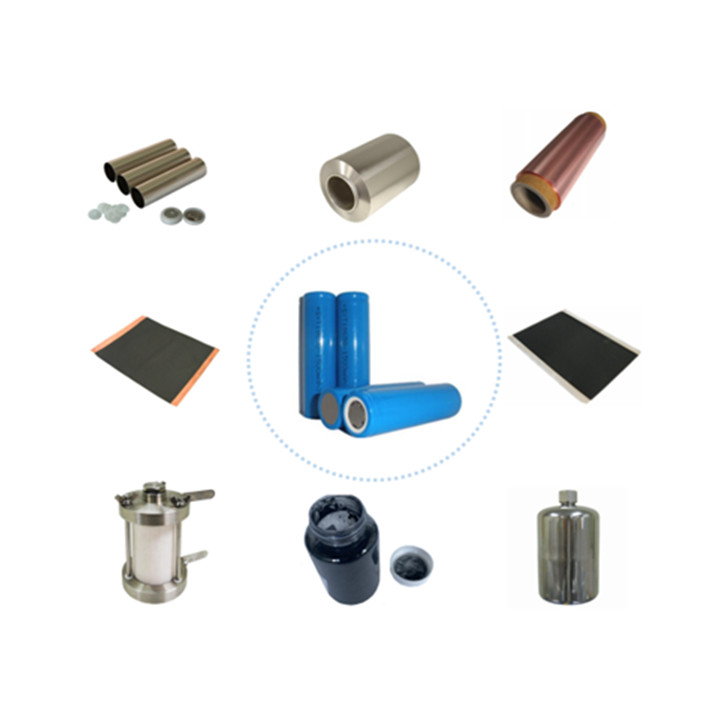

Cylindrical cell assembly equipment is used in the manufacturing process of cylindrical lithium-ion batteries, which are widely used in portable electronics, electric vehicles, and energy storage systems. This equipment facilitates the precise and efficient assembly of the battery components, including the electrodes, separator, and cylindrical casing. Here are some key types of cylindrical cell assembly equipment:

Electrode Cutting Machine: This equipment is used to cut the coated electrode sheets into precise dimensions suitable for cylindrical cell assembly. The machine can accurately trim the electrode sheets to the required width and length for the specific battery design.

Electrode Stacking Machine: The electrode stacking machine aligns and assembles the electrode sheets along with separator layers to form a jelly roll structure. It ensures proper alignment, tension control, and layering of the electrodes and separator, creating a tightly wound roll.

Can Loading Machine: The can loading machine loads the jelly roll into the cylindrical metal can, which serves as the outer casing of the battery. It accurately positions and inserts the jelly roll into the can, ready for subsequent processing.

Cap Welding Machine: Once the jelly roll is loaded into the can, the cap welding machine seals the battery by welding the top cap onto the can. This process ensures a hermetic seal and prevents leakage of the electrolyte.

Electrolyte Filling Machine: The electrolyte filling machine injects the electrolyte into the assembled cylindrical cell. The machine carefully controls the volume and ensures uniform and accurate filling of the electrolyte to achieve the desired electrolyte-to-active material ratio.

Laser Welding Machine: Laser welding equipment is used to weld the tabs or leads of the cell to the external terminals, ensuring electrical connectivity. Laser welding provides a precise and reliable connection, maintaining the integrity of the cell.

Formation and Aging Equipment: After assembly, the cylindrical cells undergo a formation and aging process to stabilize their performance. Formation equipment applies specific charging and discharging cycles to condition the cells and optimize their capacity, voltage, and overall performance.

Quality Control and Testing Equipment: Throughout the assembly process, quality control and testing equipment are essential for ensuring the reliability and performance of the cylindrical cells. This may include equipment for measuring cell voltage, capacity testing, impedance analysis, and various safety tests.

These are some of the key cylindrical cell assembly equipment types used in the production of cylindrical lithium-ion batteries. The selection and configuration of equipment may vary depending on the specific battery design, production scale, and desired manufacturing capabilities.

fr

fr en

en de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

réseau ipv6 pris en charge

réseau ipv6 pris en charge