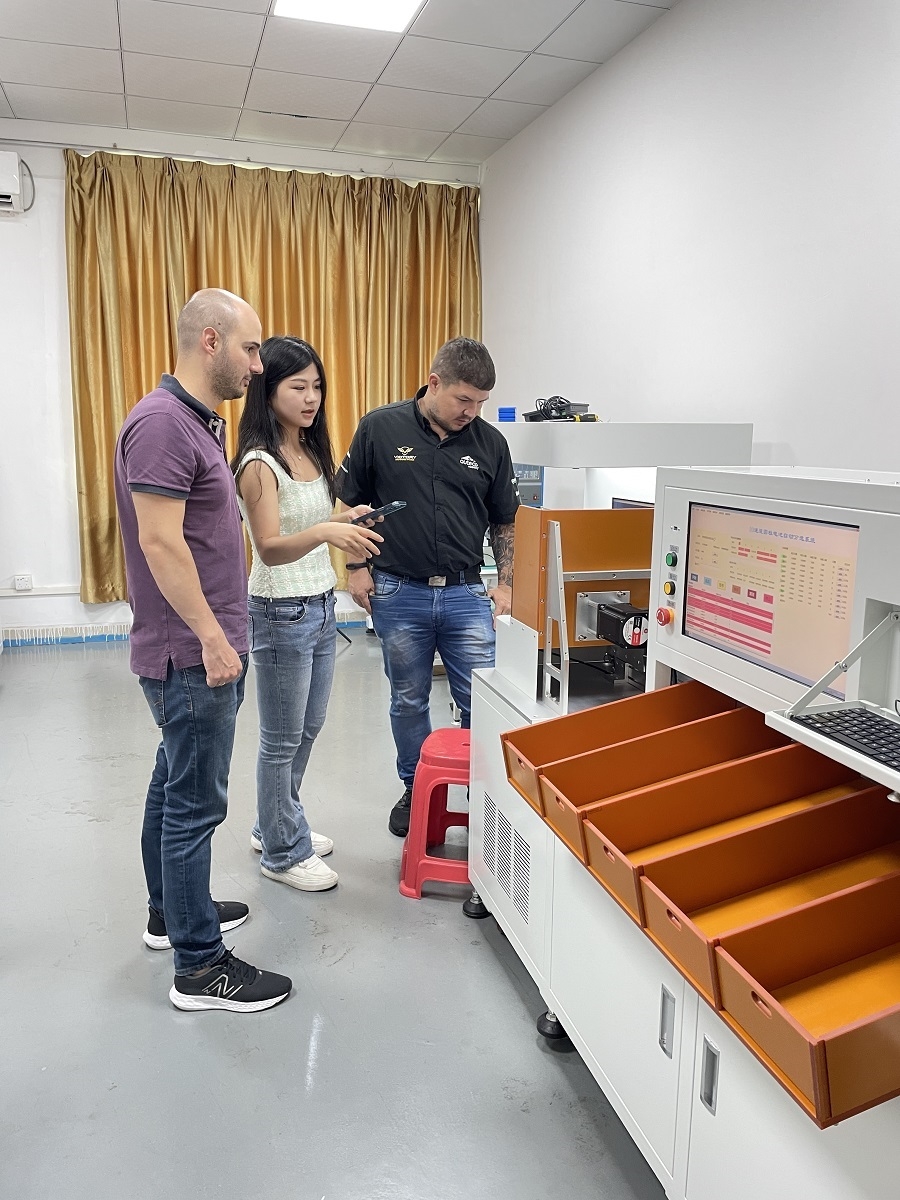

In a recent event, we had the pleasure of welcoming a group of esteemed clients from Colombia to tour our state-of-the-art battery assembly line.

The visit began with a productive meeting.The highlight of the visit was the firsthand experience of witnessing the advanced automation and high-efficiency operations of our battery assembly line equipment.

The following equipment and their functions were showcased to the visitors:

Battery Sorting Machine:This equipment automatically sorts batteries based on their internal impedance, thereby improving production efficiency and product quality.

Battery Insulation Sticker Machine: Ensuring safety and reliability, this machine applies insulation stickers to the positive poles of batteries.

Automatic Spot Welding Machine: This machine ensures a strong and reliable connection by spot welding nickel strips onto the battery packs.

CCD Tester: Used for verifying correct positioning of positive and negative poles within battery packs, guaranteeing product quality and performance.

Battery Testing Equipment: This testing apparatus thoroughly assesses battery capacity and other functionalities, ensuring compliance with high-quality standards.

The visit concluded with a group photograph, symbolizing not only the witness of collaborative potential but also the recognition of our company's achievements in the field of battery technology.

fr

fr en

en de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

réseau ipv6 pris en charge

réseau ipv6 pris en charge